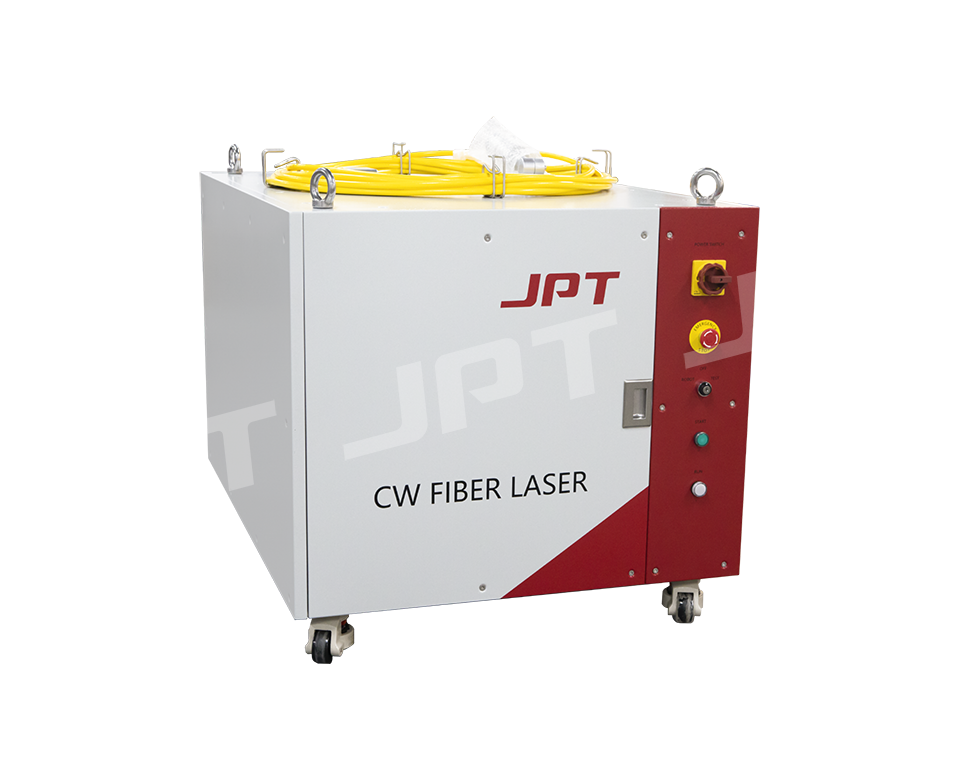

JPT CW 6000W Laser Source Laser Cutting Machine

JPT CW laser (6000W) is the optimal combination of optical, mechanical, electrical and software components. Through the controlling ports and the controlling software, the operating status of the laser can be monitored in real time, alarm messages can be received in time, and data can be collected. The laser uses water-cooling and shelf case design, with competitive advantage like high energy conversion (electric to light), low power consumption, maintenance free, fiber delivery, and easy to move & assemble, it is the most suitable laser source for industrial laser welding, cutting and other applications.

Description

JPT CW 6000W Laser Source Laser Cutting Machine

Product Characteristics

High Energy Conversion (Electric to Light)

Steady Power Delivery

Customizable Fiber Length

Less Maintenance

Output Cable (QBH QDQ+HOD)

| Parameter Unit | Unit | Parameter |

| Nominal Average Output Power | W | 6000 |

| Beam Parameter Product | mm*mrad | 3.2-4 @100μm |

| Central Emission Wavelength | nm | 1080±10 |

| Spectral Width@3dB | nm | <6 |

| Armored Cable Length | m | 25 |

| Cooling Method | / | Water Cooled |

| Operating Voltage | V | 380 ±10% |

| Maximum Power Consumption | kW | 20 |

| Switch on/off time | μs | 20 |

| Maximum Modulation Frequency | kHz | 5 |

| Operation Temperature | ℃ | 10 ~ 40 |

| Storage Temperature | ℃ | -10 ~ 60 |

| N.W | kg | 120 |

| Size(W×D×H) | mm | 911×370×709 |

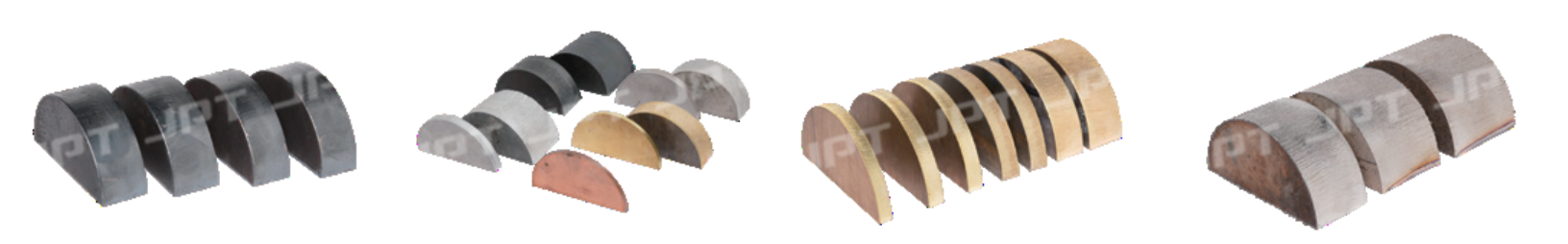

Application Advantages

Laser Cutting

Laser Welding

Surface Modiffed

Laser Cleaning

JPT CW laser (6000W) is the optimal combination of optical, mechanical, electrical and software components. Through the controlling ports and the controlling software, the operating status of the laser can be monitored in real time, alarm messages can be received in time, and data can be collected. The laser uses water-cooling and shelf case design, with competitive advantage like high energy conversion (electric to light), low power consumption, maintenance free, fiber delivery, and easy to move & assemble, it is the most suitable laser source for industrial laser welding, cutting and other applications.

Application Advantages

Carbon Steel Glossy Surrace Cutting; Metal Cutting; Metal Cutting; Thick Stainless Steel Cutting

Reviews

There are no reviews yet.