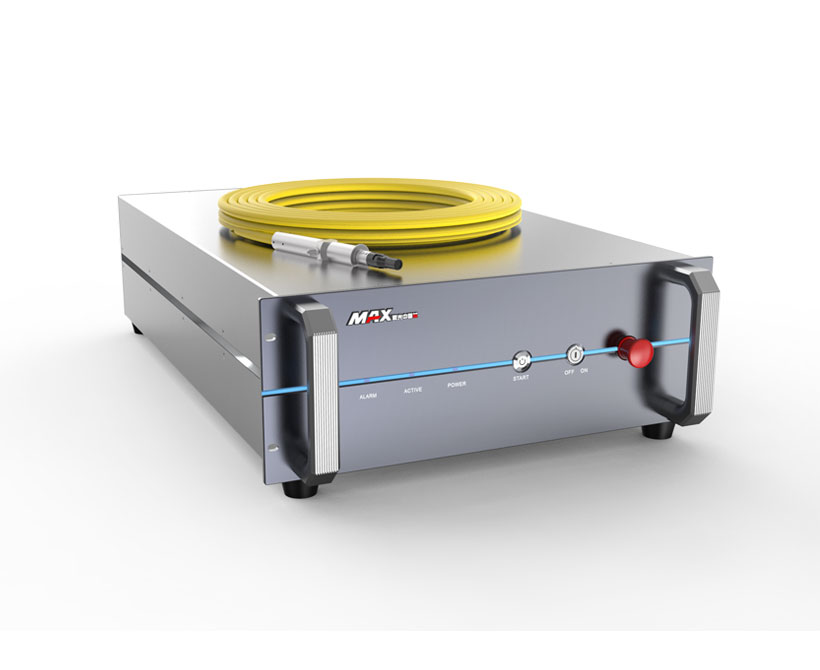

1000W-6000W CW WELDING & CLADDING FIBER LASER MAX LASER SOUECE

Main Features:

- Better beam quality vs. multi module lasers Greatly improved efficiency

- High speed in thin sheet cutting Strong capability in thick material processing

- Compact Design, Maintenance Free

- Smaller Size with Higher Stability, >60% reduction in volume Higher flexibility when integrated in to system

- High Level Vertical Integration, All key components are designed and produced in house Strict quality control, high consistency and reliability

Description

1000W~6000W SINGLE MODULE CW FIBER LASER is a high-power fiber laser with high electro-optical conversion efficiency, compact size, good beam quality and maintenance-free. Wide fiber core diameter range from 100~600um, can be customized from 800um~1000um. Mainly used in metal welding and cladding and other fields such as new energy, 3C, precision machining.

| Models | MFSC-1000W | WHSD+TSOOM | MFSC-2000W | MFSC-3000W | MFSC-4000W | MFSC-5000W | MFSC-6000W |

| OPTICAL SPECIFICATIONS | |||||||

| Nominal Power |

1000W | TSOOM | 2000W | 3000W | 4000W | 5000M | 6000M |

| Mode of Operation |

CW/Modulated | ||||||

| Polarization | Random | ||||||

| Power Tunability |

10 to 100 % | ||||||

| Wavelength | 1080±10nm | ||||||

| Power Stability |

±1% | ||||||

| Laser Beam Quality,BPP |

3.1to 3.5 mm xmrad (100μmQBH) | ||||||

| 6.4 to 7 mmx mrad (200μmQBH) | |||||||

| 10to 12 mm x mrad (300μmQBH) | |||||||

| 15to 17 mm x mrad (400μmQBH) | |||||||

| 25 to 28 mm x mrad (600μmQBH) | |||||||

| Modulation Frequency |

≤5kHz | ||||||

| Preview Red | 200 μW | ||||||

| Light Power | |||||||

| FIBER DELIVERY SYSTEM | |||||||

| Interface | QBH(LOC) | ||||||

| Length | 15/20m standard, other lengths optional | ||||||

| Diameter | 100/200/300/400/600 μm | ||||||

| Bending Radius |

200mm | ||||||

| ELECTRICAL RATINGS | |||||||

| Supply Voltage |

220VAC(-15% to +10%) Single-phase |

400VAC (-15% to +10%) 3-phase | |||||

| OTHER SPECIFICATIONS | |||||||

| Operating Temperature |

+10 to +40 ℃ | ||||||

| Storage Temperature |

-10 to+60℃ | ||||||

| Humidity | 10 to 85 % | ||||||

| Cooling Method |

Water Cooling | ||||||

| Cooling Medium |

Distilled water/ Glycol Antifreeze | ||||||

| Dimension | 800X482.6X193.2 mm | 483X950X193mm | 640X1173X1102mm | ||||

| Weight | 50(±3)kg | 55(±3)kg | 72(±3)kg | 80(±3)kg | 200(±20)kg | 240(±20) kg | |

Main Features:

- Better beam quality vs. multi module lasers Greatly improved efficiency

- High speed in thin sheet cutting Strong capability in thick material processing

- Compact Design, Maintenance Free

- Smaller Size with Higher Stability, >60% reduction in volume Higher flexibility when integrated in to system

- High Level Vertical Integration, All key components are designed and produced in house Strict quality control, high consistency and reliability

Product Feature

High Power Density with Flat-top Distribution

Cladding layer dilution rate less than 3%

High Beam Spot Concentricity

Suitable for laser welding and cladding stereolithographyReduce process commissioning time

Fiber Core Diameter Optional

800um,1000um customized optionsWider fiber core diameter range makes our laser applicable to more applications such as cladding and hardening

OBH or LOE Output

Stronger anti-reflective ability with LOE output

High Level Vertical integration

All key components are designed and produced in houseStrict quality control, high consistency and reliability

- Precision Cutting

- Metal Welding

- Sheet Metal Piercing

- Metal Carving

- Surface Treatment

- 3D Printing/Rapid Prototyping

Reviews

There are no reviews yet.