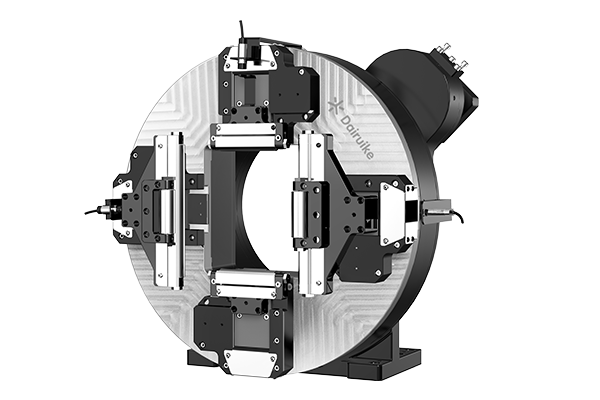

DRK24HZG-FS Rotary Laser Chuck (Front Chuck)

Square hole rotary laser chuck design enlarges processing range

Compared with the round hole chuck, it can accommodate square tubes and can process square tubes and profiles up to 230mm.

Eotary laser chuck full stroke clamping

The square-hole laser chuck has full-stroke clamping, which avoids frequent replacement of jaws and is more convenient to use.

Precise clamping

Helical gear transmission structure improves transmission efficiency and accuracy

Square hole rotary laser chuck clamps more types of pipes

Square through-hole structure design enables processing of various profiles and special-shaped pipes

Stable clamping

The rotary laser chuck comes standard with wide and narrow claws, which can achieve stable clamping of pipe fittings.

Description

DRK24HZG-FS Rotary Laser Chuck (Front Chuck)

Square hole rotary laser chuck design enlarges processing range

Compared with the round hole chuck, it can accommodate square tubes and can process square tubes and profiles up to 230mm.

Eotary laser chuck full stroke clamping

The square-hole laser chuck has full-stroke clamping, which avoids frequent replacement of jaws and is more convenient to use.

Precise clamping

Helical gear transmission structure improves transmission efficiency and accuracy

Square hole rotary laser chuck clamps more types of pipes

Square through-hole structure design enables processing of various profiles and special-shaped pipes

Stable clamping

The rotary laser chuck comes standard with wide and narrow claws, which can achieve stable clamping of pipe fittings.

Description

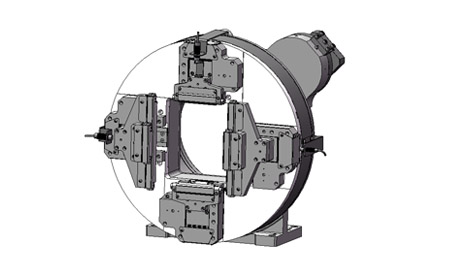

The Dairuike DRK-240FS Square Hole Full-Stroke Rotary Laser Chuck, with its innovative design and multifunctional performance, has set a new industry standard in the field of laser tube cutting. This rotary laser chuck is specially designed to meet the processing needs of various shapes and sizes of tubes, thereby completely changing the limitations of traditional round holes and ushering in a new era for the multi-type tube processing industry.

The DRK-240FS Square Hole Full-Stroke Rotary Laser Chuck features a unique square-through-hole structure design. Its most significant advantage lies in its adaptability to various shapes of tubes, including square tubes, round tubes, and various profiles. This design not only breaks the constraints of traditional round hole chucks but also greatly enhances the utilization rate of tubes, making processing more flexible and efficient.

The chuck’s processing range for tube diameters is 10 to 230mm, accommodating both square and round tubes of up to 230mm, as well as No. 20 I-beams and channel steels, setting a new record for the maximum processing diameter of square tubes in similar chucks and catering to a variety of user needs for tube processing.

The design of the DRK-240FS Square Hole Full-Stroke Rotary Laser Chuck is simple and flexible. Its full-stroke clamping function allows for uninterrupted processing without the need to change the jaws, significantly enhancing the convenience of operation and continuity of production. The 240FS rotary laser chuck uses an integrated casting and stable gearbox installation, making installation and adjustment more convenient. Its helical gear drive and fully sealed structure effectively prevent tooth jamming, reduce maintenance frequency, and extend the lifespan of the equipment.

In laser tube cutting equipment, the stability and precision of the rotary chuck are crucial. The 240FS rotary laser chuck has a very large clamping force and stronger load-bearing capacity. Its dual roller jaws, both wide and narrow, can easily clamp various shapes of tubes, ensuring stability and precision during the processing of workpieces.

With a large single-claw thrust and enhanced load-bearing capacity, the standard 220JZ laser rotary back chuck can support a weight of up to 260kg with both chucks. This provides strong support in adapting to diverse tube material needs, making it an ideal choice for users seeking high efficiency and precision in processing.

Overall, the Dairuike DRK-240FS Rotary Laser Chuck, with its efficient transmission mechanism, wide adaptability, flexible installation positions, and excellent dust-proof performance, enhances processing efficiency and quality. It has become an important device in the field of tube processing, offering users efficient and stable processing solutions. Choosing the DRK-240FS Rotary Laser Chuck means choosing a reliable and efficient industrial partner, moving towards a future of more efficient and precise processing.

Performance parameter

| OD (mm) |

Spindle Bore (mm) |

Centre-height (mm) |

Total Weight (Kg) |

Inertia (K g.cm 2) |

Repeatability (mm) |

Rotary precision mm |

| Φ615 | 245×245 | 315±0.05 | 230 | 69000 | ≤0.05 | ≤0.05 |

| Single Claw trip (mm) |

Single Claw thrust (Kg.f) |

Processing Range (mm) |

Permissible pressure (M pa) |

Rated speed (rpm) |

thickness of pipe (mm) |

Holdup time (h) |

| 115 | 220 | 10-230 | 0.3-0.8 | 150 | ≥1 | 12 |

Application

As the laser industry continues to evolve and improve, rotary laser chucks have recently made a breakthrough into a new realm in the field of laser cutting. In response to the tube forming needs of domestic and international customers, Dairuike Rotary Laser Chucks have gradually become their preferred choice. They have been successfully applied in various industries, such as sports equipment, lighting, decorative furnishings, furniture, and kitchen and bathroom appliances, all of which rely heavily on tube cutting and forming. Laser cutting of tubes not only involves fewer processes and higher efficiency, but the quality of the cut workpieces is also superior. Furthermore, it opens up even more possibilities for market development.

Reviews

There are no reviews yet.