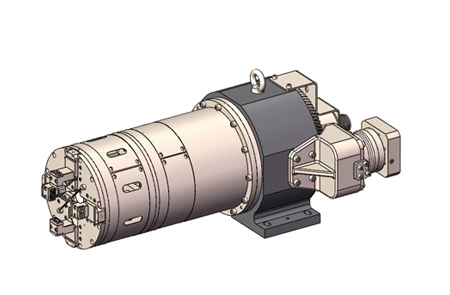

DRK32HWG-JL chuck pipe (Rear Chuck)

Easy to use

The rear jaws of the chuck pipe have a large stroke and fewer types, making the jaws more convenient to use

High rigidity

Barrel-type high-rigidity rear clamp, no fear of heavy tube clamping

Less material

The rear chuck pipe design of the gun barrel, the utilization rate of the tube can reach 90%

Flexible processing

The chuck pipe can be processed in large quantities and flexibly for various pipes, profiles and special-shaped pipes

Description

DRK32HWG-JL chuck pipe (Rear Chuck)

Easy to use

The rear jaws of the chuck pipe have a large stroke and fewer types, making the jaws more convenient to use

High rigidity

Barrel-type high-rigidity rear clamp, no fear of heavy tube clamping

Less material

The rear chuck pipe design of the gun barrel, the utilization rate of the tube can reach 90%

Flexible processing

The chuck pipe can be processed in large quantities and flexibly for various pipes, profiles and special-shaped pipes

Description

As the degree of global industrialization continues to increase, metal tubes are an important raw material necessary for various industries, and their output and consumption are also increasing. The demand for metal tube processing is also increasing. With its high speed, high efficiency and high precision, chuck pipe has become an important tool in metal pipe processing. The use of the chuck pipe can ensure the stability and precision of the metal tube during the cutting process, improving the processing efficiency and product quality. With the continuous development of technology, the performance of chuck pipe is also continuously improved, which can adapt to the processing needs of tubes of various shapes and sizes, and has become an indispensable and important tool in metal pipe processing.

The jaws of the 320 chuck pipe have a larger stroke, fewer types, and are more convenient to use. This design can improve operating efficiency, save more time, and make tube processing more efficient and convenient. At the same time, the structure of the jaws has also been optimized to increase the clamping force and ensure a firmer clamping of the tube. This design not only ensures the stability and precision of the chuck pipe, but also improves the processing efficiency of the whole machine and creates more value for users.

The 320 chuck pipe barrel has a high rigid rear clamp, which can clamp medium and heavy tubes without fear of clamping. At the same time, the use of an integral support seat structure greatly improves the stability of the support load, ensures that the pipe clamping is more firm and stable, and ensures cutting accuracy and efficiency.

The three/four chucks can be side-mounted, which means that the chuck pipe can be side-mounted on the laser tube cutting machine, which is more stable and safer than the conventional top-mounted method. The advantage of this design is that it can effectively improve the safety of loading and unloading, reduce the instability of the laser tube cutting machine, and improve production efficiency. In addition, the side-mounted design can save space and improve the overall stability and reliability of the laser tube cutting machine. Therefore, when performing high-precision tube processing, choosing a side-mounted chuck can improve operational efficiency and safety.

This chuck pipe is a supporting equipment for the laser cutting machine that can clamp and feed the tube when cutting the tube. It can clamp various specifications of round pipes, rectangular pipes, channel steels, I-beams, angle steels, special-shaped pipes, etc., taking into account all materials.

Performance parameter

| OD (mm) |

Centre-height (mm) |

Total Weight (Kg) |

Inertia (K g.cm ²) |

Repeatability (mm) |

Rotary precision (mm) |

| Φ349 | 182±0.05 | 185 | 13800 | ≤0.10 | ≤0.15 |

| Single Claw trip (mm) |

Single Claw thrust (Kg.f) |

Processing Range (mm) |

Permissible pressure (M pa) |

Rated speed (rpm) |

thickness of pipe (mm) |

| 50 | 490 | 10-320 | 0.3-0.8 | 150 | ≥2 |

Application

Sheet metal processing industry: With the rapid development of sheet metal processing technology, domestic processing technology is also advancing rapidly. Traditional sheet metal cutting equipment (shearing machines, punching machines, flame cutting, plasma cutting, high-pressure water cutting, etc.), although they occupy a considerable market share of the market, can no longer meet the current technical requirements. Laser cutting is a technological revolution in sheet metal processing and is the “processing center” in sheet metal processing. Laser cutting has high flexibility, fast cutting speed, high production efficiency, and short product production cycle, which has won a wide range of markets for customers. Laser cutting has no cutting force and no deformation during processing. No tool wear, good material adaptability. Whether simple or complex parts, the chuck pipe can be laser cut for precise rapid prototyping. It has the characteristics of fast speed, good cutting quality and material saving. Automatic and precise clamping can be realized, material utilization rate is improved, production cost is low, and economic benefit is good. The application of chuck pipes in future sheet metal processing is an inevitable trend.

Agricultural machinery industry: With the continuous development of agriculture, various agricultural machinery are also constantly updated. The types of agricultural machinery products tend to be diversified and specialized, and are divided into dozens of types according to processing capacity, processing object classification, and processing type. The upgrading of these products also puts forward new requirements for the manufacture of agricultural machinery products. The advanced laser clamping technology of chuck pipe speeds up the manufacture and development of agricultural machinery products and improves economic benefits. The production cost of agricultural machinery products is reduced.

Reviews

There are no reviews yet.