Description

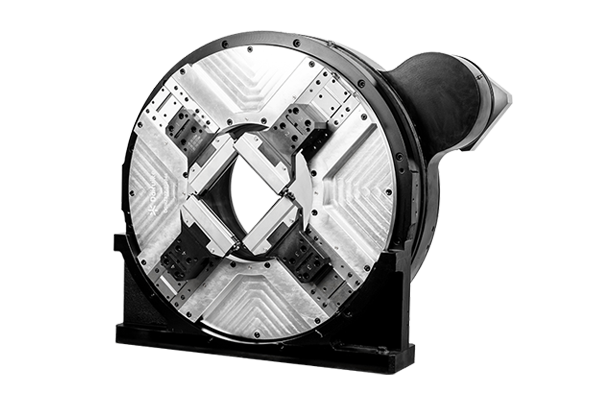

DRK32HZG-C Tube Cutting Chuck (Front Chuck)

High stability

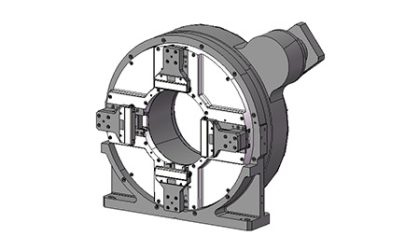

Tube cutting chuck integral support base structure improves the stability of support load

Description

Tube cutting chuck becomes more and more important,With the increase in the production and consumption of metal tubes year by year, the application of metal tubes is becoming more and more extensive, and the processing requirements for tubes are becoming more complex and diverse. In this context, laser pipe cutting machine has been widely used and recognized as an efficient and precise tube processing equipment. As a key component, the tube cutting chuck plays an important role in the tube processing process.

As a clamping tool, the tube cutting chuck can firmly fix the pipe on the laser tube cutting machine to ensure that the tube can be cut stably and accurately. During the processing of metal tubes, the performance of the tube cutting chuck directly affects the quality and efficiency of processing, so how to choose a high-quality tube cutting chuck has become the focus of attention of tube processing enterprises.

The internal transmission structure of the front chuck of the 320 tube cutting chuck has high precision, which can provide higher clamping force and a more stable clamping process. Its clamping range is 15-320mm, which can be applied to the processing needs of tubes of various sizes. In addition, the front and rear chuck clamping design of the 320 tube cutting chuck can be quickly and automatically centered to ensure stable and accurate cutting.

The 320 tube cutting chuck adopts the integrated design of the reducer, and integrates the integrated design of the bearing at the same time, so as to achieve a more compact and stable structure. The 320 tube cutting chuck gear seal design ensures that there will be no jamming due to dust entering during use. This sealing design can effectively protect internal gears and bearings, reduce maintenance frequency, prolong service life, and improve the stability and precision of the whole machine.

The tube cutting chuck adopts a high-rigidity front chuck design and short cantilever support, which makes the clamping process more stable and the clamping force stronger, and can adapt to the processing needs of various pipes. In addition, the material used in the chuck is of high quality, the processing technology is exquisite, and it has the characteristics of long life, high precision and low noise, which guarantees its reliability and stability in industrial production.

The 320 tube cutting chuck adopts a segmented clamping design, which can flexibly clamp the tube to ensure its stability and precision. Uniform clamping force, suitable for all kinds of tubes, so as to meet the different processing needs of customers.

This tube cutting chuck is a supporting equipment for the laser cutting machine that can clamp and feed the tube when cutting the tube. It can clamp various specifications of round pipes, rectangular pipes, channel steels, I-beams, angle steels, special-shaped pipes, etc., taking into account all materials.

Performance parameter

| OD (mm) |

Spindle Bore (mm) |

Centre-height (mm) |

Total Weight (Kg) |

Inertia (K g.cm 2) |

Repeatability (mm) |

Rotary precision mm |

| Φ760 | Φ325 | 385±0.05 | 334 | 132000 | ≤0.05 | ≤0.05 |

| Single Claw trip (mm) |

Single Claw thrust (Kg.f) |

Processing Range (mm) |

Permissible pressure (M pa) |

Rated speed (rpm) |

thickness of pipe (mm) |

Holdup time (h) |

| 70 | 480 | 15-320 | 0.3-0.8 | 100 | ≥1 | 12 |

Application

Reviews

There are no reviews yet.