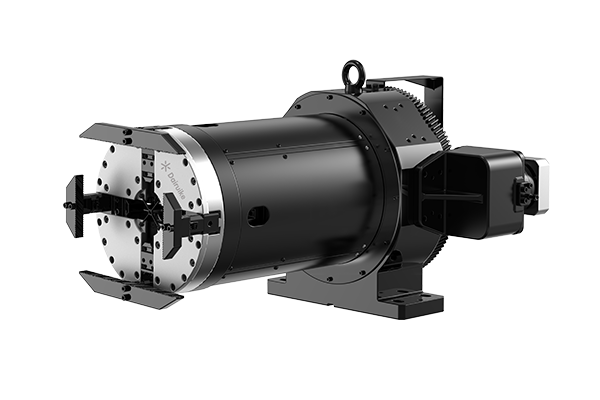

DRK36HWG-JL pneumatic chuck ( Rear Chuck )

Easy to use

Fiber laser pneumatic chuck rear chuck jaws have a large stroke and fewer types, making the jaws more convenient to use

High rigidity

Gun barrel type high rigidity rear chuck, no fear of heavy tube clamping

Less residual material

Fiber laser pneumatic chuck barrel type rear chuck design, tube utilization rate of more than 90%

Flexible processing

Large capacity, flexible for processing various tubes, profiles and shaped tubes

Description

DRK36HWG-JL pneumatic chuck ( Rear Chuck )

Easy to use

Fiber laser pneumatic chuck rear chuck jaws have a large stroke and fewer types, making the jaws more convenient to use

High rigidity

Gun barrel type high rigidity rear chuck, no fear of heavy tube clamping

Less residual material

Fiber laser pneumatic chuck barrel type rear chuck design, tube utilization rate of more than 90%

Flexible processing

Large capacity, flexible for processing various tubes, profiles and shaped tubes

Description

The heavy tube market is an expanding and growing market, mainly in construction, bridges, machinery manufacturing, petrochemicals and other applications. The demand for tubes in these industries is increasing, especially for heavy tubes with large diameter and wall thickness, and how to process these tubes efficiently and precisely has become an important issue. Pneumatic chuck, as a kind of efficient and precise tube processing equipment, can effectively solve these problems. As an important part of laser tube cutting machine, pneumatic chuck plays a vital role in clamping and fixing the tubes. With the expanding market, pneumatic chuck is also innovating and developing to meet the needs of various tube processing, becoming an important support and guarantee in the field of tube processing.

The 360FS pneumatic chuck rear chuck adopts a highly rigid gun barrel design with a large clamping stroke and clamping force, which is capable of clamping tubes of various sizes. Also, with fewer types of rear chuck jaws, the chuck also features pneumatic control for fast clamping and loosening of tubes, saving processing time and labor costs while ensuring accurate clamping and stable processing of tubes. The integral support base structure can improve the stability of the support load to avoid tube deformation and cutting errors.

The 360FS pneumatic chuck rear chuck is a special chuck for large tube processing. The 360FS pneumatic chuck front chuck is capable of clamping larger diameter tubes to meet the needs of heavy metal tube processing. The rear chuck has a large clamping stroke that extends beyond the range of the front chuck for maximum tube savings. 360FS pneumatic chuck Rear Chuck has a wide clamping range and can clamp any tube from 20-360mm. In addition, the rear chuck comes standard with a reducer mount for flexible installation of a reducer. The single jaw design of the Dairuike 360FS pneumatic chuck rear chuck is being promoted and enhanced to provide a stronger clamping force than traditional processing dies, with a single tube load capacity of up to 1 ton, making it suitable for larger tube processing needs. It has become the choice of more and more heavy tube field.

Laser tube cutters equipped with three/ four chucks can achieve zero tail cutting and avoid material waste, thus achieving material saving and cost saving. This configuration can not only improve productivity, but also greatly reduce the investment of manpower and material. With the continuous development of laser tube cutting technology, equipped with three chucks / four chucks has become the preferred configuration for many manufacturers.

This pneumatic chuck is a laser cutting machine that can achieve the clamping and feeding of the tube when the laser cutting machine supporting equipment. It can clamp all kinds of specifications of round tube, rectangular tube, channel steel, I-beam, angle steel, shaped tube etc., the whole material to take into account.

About the maintenance of the fiber laser pneumatic chuck

The maintenance of the fiber laser pneumatic chuck is very important for the normal operation of the equipment and high cutting effect. The following are the basic steps and precautions for chuck maintenance:

For different workpieces, it is necessary to choose an appropriate clamping method or make a special fixture for clamping. The fiber laser pneumatic chuck is suitable for workpieces with symmetrical tubes. The standard chuck can not only clamp conventional tubes, but also clamp various special-shaped tubes.

Good chuck lubrication can ensure high precision after long-term use. However, wrong or inappropriate lubrication can cause various problems such as weakened gripping force, reduced gripping accuracy, abnormal wear, etc. Therefore, it must be operated according to the requirements when lubricating.

After the processing is completed, use a high-pressure air gun or similar tools to clean the chuck body and slideway surface of the metal laser pipe cutting machine. It is recommended to remove the jaws of the chuck every 6 months for cleaning and lubrication. At the same time, check whether the parts are broken or worn. If there are seriously worn parts, they should be replaced immediately. After checking and ensuring that there is no abnormality, apply lubricating oil to the sliding surface of the jaws again, and then assemble and use.

Correct maintenance and maintenance measures can prolong the service life of the fiber laser pneumatic chuck and ensure the normal operation of the equipment and the stability of high cutting effect. For specific use and care instructions, please refer to the device’s user manual or consult the manufacturer for accurate information.

Performance Parameter

| OD mm |

Centre-height mm |

Total Weight kg |

Inertia Kg.cm2 |

Repeatability mm |

Rotary precision mm |

| Φ355 | 275±0.05 | 320 | 43000 | ≤0.10 | ≤0.15 |

| Single Claw trip mm |

Single Claw thrust Kg.f |

Processing Range mm |

Permissible pressure Mpa |

Rated speed rpm |

thickness of pipe mm |

| 107.5 | 1000 | 15-360 | 0.3-0.8 | 100 | ≥2 |

Application

Metal pipes are widely used in fitness equipment manufacturing, chemical pipelines, heavy industry manufacturing and other industries. In different application scenarios, the required pipe shapes, diameters, weights, thicknesses, etc. are not the same, which puts forward more requirements for metal pipe cutting technology. high demands.

The traditional methods of cutting heavy-duty pipes mainly include flame cutting and plasma cutting. Limited by the cutting level of the operator, the finished product has many defects and poor quality, and it is easy to cause repeated cutting due to cutting quality problems, which wastes time and pipe material costs.

Kitchenware manufacturing industry: Nowadays, people have higher requirements for the quality of life, and the demand for kitchenware and related products has increased. The fiber laser pneumatic chuck is more suitable for clamping stainless steel, with fast speed, high precision and good effect, and can speed up production and processing and shorten delivery time. In the kitchenware processing industry, the traditional processing method is low in efficiency, consumes a lot of pipe materials, and has high cost of use, which restricts the development of new products.

The emergence of the fiber laser pneumatic chuck has solved the problem that has been plagued by kitchenware manufacturers. Use fiber laser pneumatic chuck to process tubes and quickly develop new products. At the same time, the cutting precision of laser processing equipment is extremely high, which improves the yield of pipes. For some special-shaped pipes, laser cutting chucks have unique advantages.

Lighting Industry: Outdoor luminaires are large tubes that need to be cut into different types. The traditional cutting method is inefficient and cannot satisfy the individualized development. fiber laser pneumatic chuck can solve this problem very well.

Reviews

There are no reviews yet.