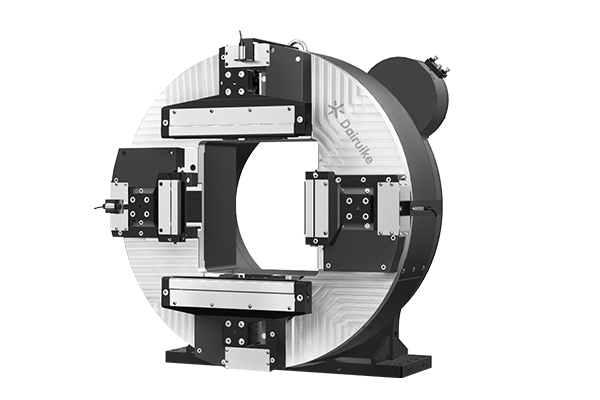

DRK36HZG-FS Self Centering Chuck (Front Chuck)

Full stroke clamping

self centering chuck Full-stroke clamping, no need to replace the jaws, greatly simplifying the operating steps and improving work efficiency

Square chuck structure, wide processing range

Break through the round hole limitation, the same self centering chuck size of the processing range is further expanded

The variety of profiles is increased

Square through-hole structure design, realize a variety of profiles and shaped tube processing

High clamping force

The self centering chuck is equipped with slotted steel jaws as standard, and the load capacity of two chucks can reach 1000KG

Description

DRK36HZG-FS Self Centering Chuck (Front Chuck)

Full stroke clamping

self centering chuck Full-stroke clamping, no need to replace the jaws, greatly simplifying the operating steps and improving work efficiency

Square chuck structure, wide processing range

Break through the round hole limitation, the same self centering chuck size of the processing range is further expanded

The variety of profiles is increased

Square through-hole structure design, realize a variety of profiles and shaped tube processing

High clamping force

The self centering chuck is equipped with slotted steel jaws as standard, and the load capacity of two chucks can reach 1000KG

Description

Self centering Chuck is becoming more and more popular, Indeed, the rapid growth of the global economy and the booming industrial manufacturing sector in recent years have resulted in high demand for raw materials. In large industries, heavy metal tubes are in high demand. Heavy metal pipes are widely used in construction, energy, transportation, machinery manufacturing and other fields, such as bridges, building structures, oil and gas pipelines, shipbuilding, etc. The development of the industry has driven the increase in the use of heavy metal pipes, and also the development of related industries. Heavy metal tubing plays an important role in industrial manufacturing, providing a strong and reliable support and transmission system for engineering projects. As the global industry continues to develop, the demand for heavy metal pipes will continue to grow, making an important contribution to economic prosperity and modernization.

Self centering chuck is one of the main equipment for metal pipe processing, but traditional laser pipe cutting machines are often limited by the following points when processing heavy pipes: the length of the pipe, the diameter of the pipe, the weight of a single pipe and the weight of the pipe. type of metal. Because the traditional cutting method can only process round pipes and square pipes within 6 meters, the quality of a single pipe is also limited, and it cannot be well qualified for cutting heavy pipes. Based on the pain points of users in heavy tube processing, Dai Ruike developed a new type of self centering chuck specially for heavy tube processing. Let’s take a look at the highlights of this self centering chuck!

DRK-360FS self centering chuck upgrade square hole through-hole design, to achieve a variety of types of material and shaped tube processing, is a heavy self centering chuck developed for the broadening of the heavy tube market, powerful, professional processing of heavy tube rotary pneumatic chuck, is a high load-bearing high-precision high-performance pipe cutting machine heavy series of rotary pneumatic chuck for the development of 360mm or less tube, and DRK-360 round hole rotary pneumatic chuck Compared with DRK-360FS square hole self centering chuck, it can clamp up to 360mm square tube.

The DRK-360FS heavy rotary pneumatic chuck improves the conventional round hole chuck, solves the processing of medium and heavy tubes, and at the same time, the size range of the processed tubes is larger, the load capacity is larger, more in line with the market demand for heavy tubes.

Heavy tube cutting machine self centering chuck upgrade, using heavy centering chuck, chuck clamping force increased, pipe load-bearing capacity enhanced, greatly meet the medium-sized, heavy type tube laser cutting, to ensure the stability of processing and tube cutting accuracy.

This self centering chuck is a can realize the cutting tube clamping and tube feeding laser cutting machine supporting equipment. Can clamp all kinds of specifications of round tube, rectangular tube, channel steel, I-beam, angle steel, shaped tube, etc., the whole material to take into account. Full-stroke clamping, no need to replace claws, more convenient to use.The laser cutting machine rotary pneumatic chuck with wide and narrow clamping, stable clamping to adapt to a variety of profiles, anti-seize, clamping force, to achieve large, heavy tube stable clamping, integral built-in drive, good dustproof, accurate and stable transmission, reducer multi-angle selection, convenient installation.

This self centering chuck provides a very efficient solution for heavy tubes and large diameter tubes, the processing range is increased and the load capacity is improved. rotary pneumatic chuck front chuck helical gear transmission, improve transmission efficiency and precision.

DRK-360FS heavy self centering chuck equipment has the advantages of high efficiency, good quality and wide application compared with traditional processing equipment, which is the first choice for heavy tube processing. Three/four chucks with optional side hanging, safer loading and unloading, multiple clamping with cutting mode, high clamping strength, zero tail material cutting, and improved tube utilization.

Performance Parameter

| OD mm |

Spindle Bore mm |

Centre-height mm |

Total Weight kg |

Inertia Kg.cm2 |

Repeatability mm |

Rotary precision mm |

| Φ890 | 370×370 | 465±0.05 | 660 | 400000 | ≤0.05 | ≤0.05 |

| Single Claw trip mm |

Single Claw thrust Kg.f |

Processing Range mm |

Permissible pressure Mpa |

Rated speed rpm |

thickness of pipe mm |

Holdup time h |

| 176 | 920 | 20-360 | 0.3-0.8 | 50 | ≥3 | 12 |

Application

The wide application of heavy self centering chuck has covered many industries, including heavy industry machinery, steel structure construction, building construction, machinery manufacturing, bridge engineering, greenhouses, communication towers, etc. By breaking the limitations of traditional laser cutting equipment, it realizes the cutting of various types of pipes, including round pipes, square pipes, channel steel, angle steel, oval pipes, etc., which broadens the processing field and has high usability.

The heavy rotary self centering chuck solves the previous difficulties in the processing of large-diameter pipes. It completely solves the problem of oversized, overlong and overweight pipes. Through the heavy rotary pneumatic chuck with large diameter and automatic centering, the center of the pipe can be accurately positioned to achieve high-precision and stable cutting, thereby improving processing efficiency. This innovative processing method fills in the shortcomings of traditional processing methods and brings more efficient and precise processing solutions to the industry.

The heavy self centering chuck has high precision when dealing with heavy metal tubes, cutting zero tailings, saving a lot of consumables, saving a lot of labor costs and shortening the construction period. Therefore, the heavy self centering chuck can be regarded as the filling of the conventional laser pipe cutting chuck, which broadens the scope of its processing field.

Reviews

There are no reviews yet.